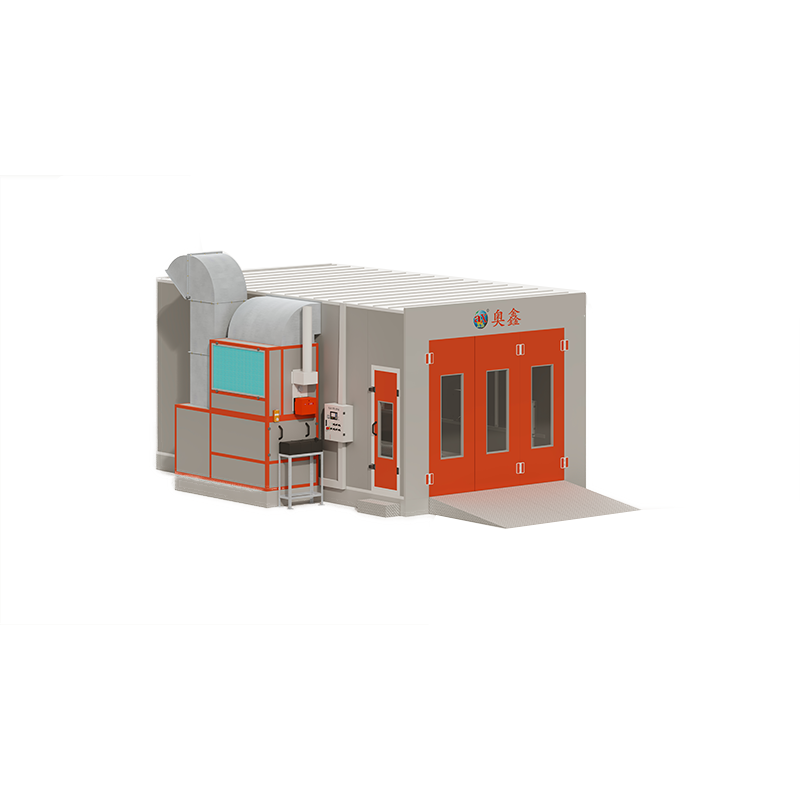

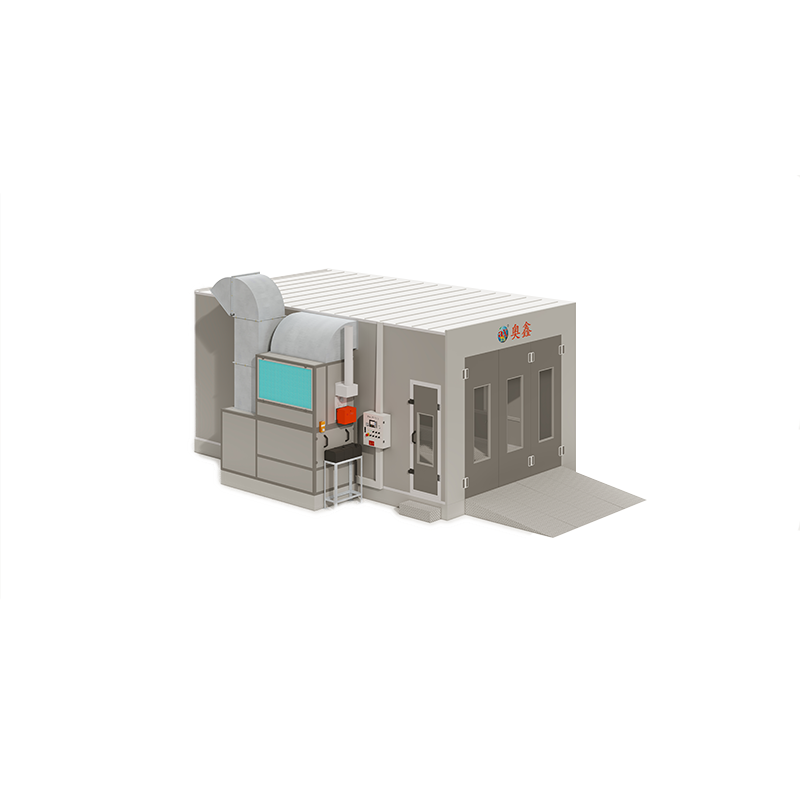

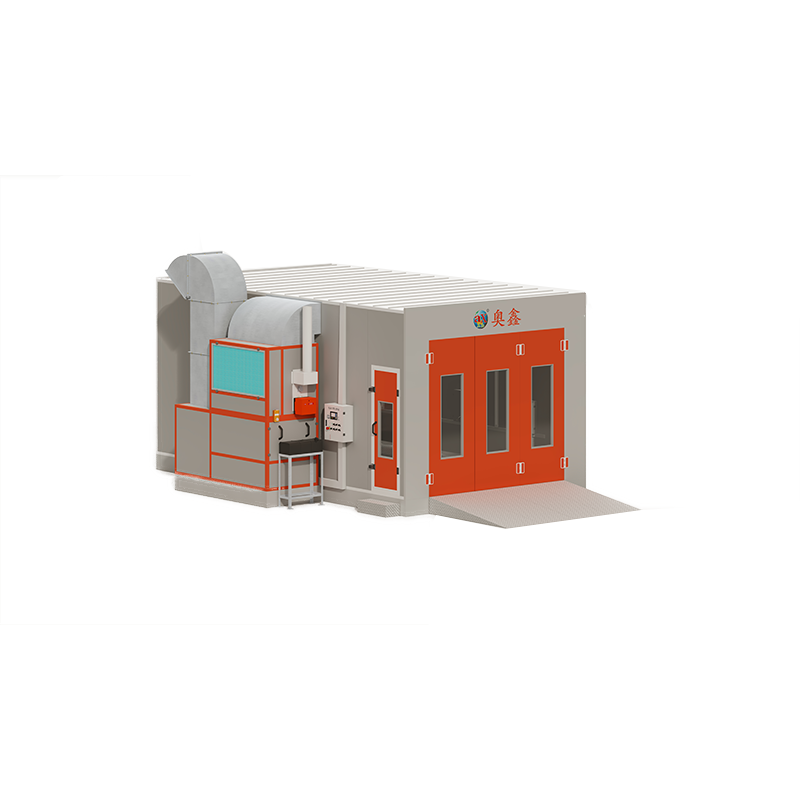

paint spray booth manufacturer

At the forefront of paint finishing technology stands our esteemed paint spray booth manufacturer, renowned for crafting precision equipment tailored for the most demanding of applications. The main functions of these state-of-the-art spray booths include providing a controlled environment for applying paint, minimizing overspray, and ensuring the highest quality finish. Technological features are the backbone of these booths, boasting advanced filtration systems, energy-efficient lighting, and precision temperature control to optimize conditions for both operator comfort and paint application. These innovations are not just for show; they are designed for real-world applications across industries such as automotive, aerospace, and industrial manufacturing, where the quality of the finish is paramount.