گسترش قابلیتها با کابینتهای صنعتی رنگپاشی

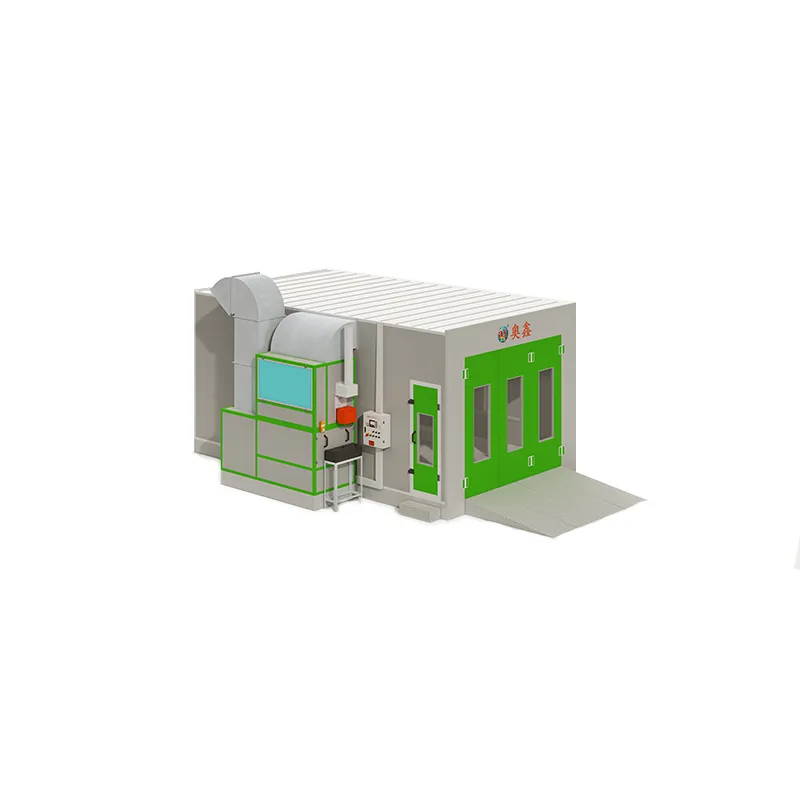

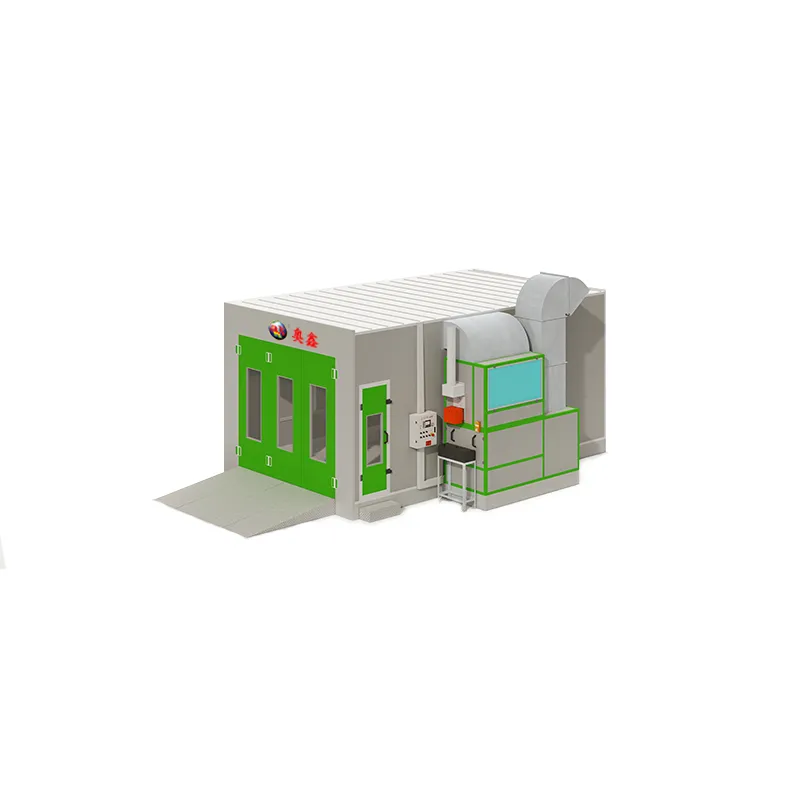

فرآیندهای نوین تولید و پرداخت نهایی، نیازمند یکنواختی، تمیزی و کیفیت هستند. از میان نوآوریهای بسیاری که به تحقق این استانداردها کمک میکنند، غرفه رنگ صنعتی یکی از اساسیترین ابزارها محسوب میشود. این محیطهای بسته یا نیمهبسته، فضای کنترلشدهای برای رنگکاری انواع محصولات از جمله خودروها و قطعات هواپیما فراهم میکنند. طراحی شده بهگونهای که کیفیت هوا، رطوبت و پاشش اضافی را مدیریت میکنند، کابینتهای رنگپاشی صنعتی در بسیاری از صنایع بیبدیل هستند.

درک روشهای متنوعی که یک غرفه رنگ صنعتی استفاده از آن میتواند به شرکتها در تصمیمگیریهای آگاهانه در مورد طراحی تأسیسات، اهداف بهرهوری و ایمنی کارکنان کمک کند. انعطافپذیری این سیستمها فراتر از تنها اعمال رنگ است؛ این سیستمها در رعایت استانداردها، بهینهسازی پایانهها و افزایش بهرهوری نیز نقش دارند.

کاربردهای متنوع در بخشهای خودرویی

تولید خودرو و خطوط مونتاژ

یکی از رایجترین کاربردهای کابین رنگ صنعتی در بخش خودرو است. در کارخانههای بزرگ تولید و همچنین کارگاههای کوچک تعمیر، داشتن پوشش رنگی یکنواخت و با کیفیت ضروری است. کابینهای رنگ صنعتی در خطوط مونتاژ خودرو محیطی بدون گرد و غبار و با دمای کنترلشده فراهم میکنند. این امر تضمین میکند که خودروهای جدید دارای پوششی بینقص باشند که در برابر خراشیدگی، زنگزدگی و فرسایش محیطی مقاومت میکنند.

تولیدکنندگان مدرن خودرو از بازوی رباتیک درون کابینهای رنگ صنعتی استفاده میکنند تا پوشش یکنواخت را تضمین کنند. این کابینها اغلب با تنظیمات دقیق زمانبندی و جریان هوا کار میکنند تا اطمینان حاصل شود که هر لایه بهطور یکنواخت اعمال شده و در شرایط بهینه پخته میشود.

تعمیرگاههای خودرو و بدنهسازی

بدنهکارها از کابینهای رنگ صنعتی برای بازگرداندن خودروها به وضعیت اولیه آنها پس از تصادفات یا فرسایش استفاده میکنند. ماهیت بسته این کابینها اطمینان میدهد که کارهای رنگپاشی تحت تأثیر آلایندههای خارجی مانند گرد و غبار، رطوبت یا ذرات معلق در هوا قرار نگیرند. علاوه بر این، استفاده از کابین رنگ صنعتی در کارهای تعمیری به رعایت مقررات زیستمحیطی سختگیرانه و کدهای بهداشتی کمک میکند و از تکنسین و جامعه اطراف نیز حفاظت میکند.

رنگکاری تجهیزات و ماشینآلات صنعتی

تجهیزات سنگین

بخشهایی مانند کشاورزی، ساختوساز و معادن اغلب به ماشینآلات سنگین و مقاومی متکی هستند که نیازمند پوششهای مقاوم در برابر خوردگی و فرسایش هستند. کابینهای رنگآمیزی صنعتی در فراهمکردن محیط مناسب برای اعمال این پوششهای ویژه بر روی ماشینآلات بزرگ مانند بیلهای موتوری و لودرها ضروری هستند.

اندازه و انعطافپذیری برخی از کابینهای رنگآمیزی صنعتی آنها را به انتخاب مناسبی برای تجهیزات بزرگ تبدیل میکند. با سیستمهای قابل تنظیم فشار هوا و فیلتراسیون، این کابینها اطمینان حاصل میکنند که پوششهای محافظ به گونهای اعمال شوند که خطر آلودگی ناشی از اسپری بیش از حد وجود نداشته باشد.

ساخت قطعات و مؤلفههای صنعتی

حتی قطعات کوچک ماشینآلات نیز به دقتی نیاز دارند که تنها یک محیط کنترلشده میتواند فراهم کند. کابینهای رنگآمیزی صنعتی برای اعمال پوششهای نهایی بر روی اجزایی مانند چرخدندهها، نگهدارندهها، قابهای فلزی و لولهکشی استفاده میشوند. این امر انسجام در تولید انبوه را تضمین میکند، بهویژه زمانی که قطعات باید در معیارهای خاص زیبایی یا مقاومت در برابر خوردگی مطابق باشند.

پایانکار هواپیمایی و هوافضا

مونتاژ هواپیما

در تولیدات هوافضایی، دقت و عملکرد از اهمیت بالایی برخوردار است. یک کابین رنگ صنعتی برای رنگکردن قطعات هواپیما، بدنهها و حتی کل هواپیماها استفاده میشود. این کابینها بهگونهای طراحی شدهاند که الکتریسیته ساکن، جهت جریان هوا و دما را کنترل کنند تا از پوشش نامساوی یا خطر آتشسوزی جلوگیری شود.

رنگ استفادهشده روی هواپیماها باید بتواند در برابر اصطکاک شدید هوا، تغییرات دما و قرارگیری در معرض عناصر سختگیرانه مقاومت کند. تنها راه برای تضمین چنین دوامی استفاده از یک کابین رنگ صنعتی است که محیطی بدون گرد و غبار و با تهویه هوا بهصورت یکنواخت فراهم کند.

نگهداری و رنگآمیزی مجدد

شرکتهای هواپیمایی از کابینهای رنگ صنعتی برای رنگکردن دورهای و رنگآمیزی مجدد هواپیماها استفاده میکنند. چه در حال بهروزرسانی برندینگ هستند و چه در حال تعمیر نقصهای ظاهری، این کابینها اطمینان میدهند که پوششها بهصورت حرفهای اعمال شوند. وقفه در صنعت هوانوردی هزینهبر است و کارایی یک کابین رنگ بهخوبی مجهز میتواند زمان بازگشت هواپیما را بهطور قابلتوجهی کاهش دهد.

کاربردهای دریایی و کشتیسازی

پوششهای قایق و کشتی

Follow the structure below as an example:

Ensure that the output is a valid JSON object with only the translated text values.

Do not include any explanations, markdown formatting, or additional text.

Technical Terms:

Translate technical terms if they have an equivalent in Persian.

Do not leave internationally recognized technical terms (like “E-glass”) untranslated unless they are standard across languages.

شرکتهای مبلمان از کابینهای رنگپاش صنعتی برای اعمال رنگهای تیره، آببندیکنندهها و پوششهای نهایی روی محصولات چوبی استفاده میکنند. محیطی بدون گرد و غبار برای دستیابی به پوششهای براق و صاف که مشتریان درخواست میکنند، ضروری است. این کابین همچنین فرآیند پخت کنترلشدهتری را فراهم میکند و باعث افزایش دوام محصول میشود.

از آنجا که چوب به رطوبت و دما واکنش نشان میدهد، یک کابین رنگپاش صنعتی با کنترل آبوهوای دقیق، محیط ایدهآلی برای دستیابی به نتایج یکنواخت فراهم میکند. تولیدکنندگان میتوانند رنگآمیزی را مطابق با نیازهای خط تولید خود تنظیم کنند و همزمان از کار مجدد بکاهند.

کابینت و تجهیزات داخلی

کابینهای رنگپاش صنعتی همچنین بهطور گسترده در تولید کابینتهای آشپزخانه، وانیتیها و دیگر وسایل داخلی استفاده میشوند. یکنواختی در اعمال رنگ در هنگام تولید انبوه مجموعهها یا رنگآمیزیهای هماهنگ بسیار حیاتی است. یک کابینک مجهز، هم کارایی و هم کنترل کیفیت را فراهم میکند.

کاربردهای نظامی و دفاعی

پوششهای خودروهای نظامی

پیمانکاران دفاعی از کابینهای رنگآمیزی صنعتی برای اعمال پوششهای شبهرنگ یا ضد خوردگی روی خودروهای نظامی استفاده میکنند. این پوششها نه تنها در برابر عوامل محیطی محافظت میکنند، بلکه مزایای تاکتیکی نیز فراهم میکنند. کابین فضای بهینهای برای اعمال پوششهای تخصصی فراهم میکند که باید استانداردهای دفاعی سختگیرانه را برآورده کنند.

تجهیزات و قطعات سلاحخانه

از کلاههای ایمنی تا قطعات سلاح، قطعات کوچک در بخش دفاعی نیز به پوششهای دقیق و مقاوم نیاز دارند. استفاده از کابین رنگآمیزی صنعتی اطمینان میدهد که حتی اشکال پیچیده نیز پوشش یکنواختی دریافت کنند. سیستمهای مناسب جریان هوا و فیلتراسیون خطر جمع شدن یا روان شدن رنگ را کاهش میدهند.

مزایا برای ایمنی و انطباق

سلامت و ایمنی کارکنان

استفاده از کابین رنگآمیزی صنعتی تنها مربوط به بهبود محصول نهایی نیست، بلکه مربوط به حفاظت از کارگر نیز هست. کابینها با سیستمهای تهویه مناسب تجهیز شدهاند که بخارات مضر و ذرات معلق را از هوا خارج میکنند و در نتیجه قرار گرفتن در معرض ترکیبات آلی فرار (VOCs) کاهش مییابد.

سیستمهای داخلی خاموشکننده آتش و روشنایی کنترلشده نیز به ایمنی کلی کمک میکنند. کارفرمایانی که در تجهیزات رنگکاری صنعتی سرمایهگذاری میکنند، نشان از تعهد خود نسبت به سلامت کارکنان و رعایت مقررات دارند.

مقررات مربوطه

رنگکاری صنعتی تحت نظارت مقررات سختگیرانه زیستمحیطی و ایمنی شغلی قرار دارد. کابینهای رنگکاری صنعتی به شرکتها کمک میکنند تا با حبس کردن انتشارات، مدیریت پسماندها و کنترل رنگپاش از دستورالعملها پیروی کنند. چه برای EPA، OSHA یا مقررات محلی، یک کابین سرمایهگذاری در مدیریت ریسک و ثبات عملیاتی بلندمدت است.

افزایش کارایی و بهره وری

زمانهای چرخش سریعتر

به دلیل محیط کنترلشده و شرایط خشککننده بهینهسازیشده، کابینهای رنگکاری صنعتی بهطور قابلتوجهی زمان خشکشدن را کاهش میدهند. در صنایعی که سرعت اهمیت دارد — مانند تعمیرات خودرو یا نگهداری هوانوردی — این فایده بهتنهایی میتواند منجر به صرفهجویی قابلملاحظهای در هزینهها شود.

علاوهبراین، سیستمهای اتوماتیک در برخی از این کابینها میتوانند رنگ را بهصورت کارآمدتری نسبت به روشهای دستی اعمال کنند و این امر باعث کاهش خطاها و کارهای اضافی میشود.

کنترل کیفیت بهبود یافته

کابینهای صنعتی رنگ به استانداردسازی کیفیت در سراسر تولید و شیفتها کمک میکنند. با حذف تغییرات محیطی، تولیدکنندگان میتوانند یکنواختی را در بافت، ضخامت و رنگ حفظ کنند. این موضوع نه تنها باعث کاهش ضایعات میشود، بلکه رضایت مشتری را نیز افزایش میدهد.

سوالات متداول

عملکرد اصلی یک کابین صنعتی رنگ چیست؟

هدف اصلی یک کابین صنعتی رنگ فراهم کردن یک محیط کنترلشده برای اعمال رنگ و پوششها است که ایمنی، یکنواختی و کیفیت را تضمین میکند.

کدام صنایع بیشترین استفاده را از کابینهای صنعتی رنگ میبرند؟

صنایعی مانند خودرو، هوافضا، دریایی، مبلمان و دفاع از کابینهای صنعتی رنگ بهطور گستردهای برای داشتن پایان دادن با کیفیت بالا و رعایت استانداردهای ایمنی استفاده میکنند.

کابین صنعتی رنگ چگونه ایمنی را بهبود میبخشد؟

ایمنی را با کنترل بخارات خطرناک، مدیریت جریان هوا و کاهش خطر آتش سوزی یا قرار گرفتن در معرض استنشاق بهبود میبخشد و در نتیجه محیط کاری ایمنتری برای رنگکاران و تکنسینها ایجاد میکند.

آیا میتوان غرفههای رنگپاشی صنعتی را مطابق با نیازهای خاص سفارشیسازی کرد؟

بله، بسیاری از غرفههای رنگپاشی صنعتی به صورت ماژولار هستند و از نظر اندازه، پیکربندی جریان هوا، کنترل دما و سیستمهای فیلتراسیون قابل سفارشیسازی هستند تا نیازهای منحصر به فرد صنایع مختلف را برآورده کنند.

فهرست مطالب

- گسترش قابلیتها با کابینتهای صنعتی رنگپاشی

- کاربردهای متنوع در بخشهای خودرویی

- رنگکاری تجهیزات و ماشینآلات صنعتی

- پایانکار هواپیمایی و هوافضا

- کاربردهای دریایی و کشتیسازی

- Translate technical terms if they have an equivalent in Persian.

- کاربردهای نظامی و دفاعی

- مزایا برای ایمنی و انطباق

- افزایش کارایی و بهره وری

- سوالات متداول