Conservare Ambiente Purgare

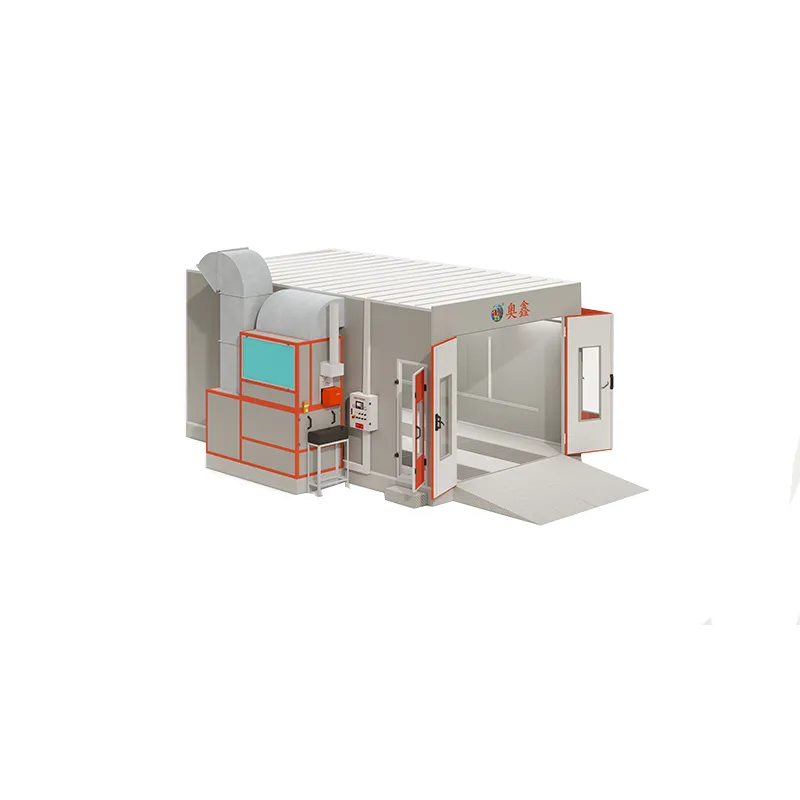

In fabricatione industriali, conservare spatium sine pulvere et bene ventilatum est necessarium ad efficiendum opus perfectum. Hic loco cabinæ vernici industrialis præstare non possunt. A industrial Poena Booth præstare non potest. Cabinæ vernici industrialis validæ non solum processus verniciationis præcisæ adiuvant sed etiam munere primario funguntur in regimine qualitatis aeris per totum locum laboris. Propositus huius articuli est investigare quomodo hæc loca gestionem aeris, filtrationis et impactionis ambientis moderentur, interea dum tutetatem operariorum et legum complentiam custodiunt.

Systemata Filtrationis Aeris in Cabinis Vernici Industrialibus

Officium Præfiltrationis et Filtrorum Introduci

Elementum clavis in un industrial Poena Booth est systema filtrationis eius. Praefiltratio incipit antequam aer ad cellam ingreditur. Filtra advehi magna corpora et contaminantes e foris capiunt ut aer purus et partibus carens ad locum operis perveniat. Haec filtra saepe stratificata sunt ut et maiores et minores particulas arripiant, ita efficaciam et vitae spatium subsequentium filtrationis graduum multum meliorantes.

Importancia Filtrorum Exhalationis

Filtris exhalationis opus est pro arripiscendis pulveris supervacui et volatilibus compositis organici (VOCs) quae noxiae operariis esse possunt et noxae ambiente. Systemata cellarum picturae saepius usitantur multi-stadia filtra exhalationis, inter quae strata vitrofibrae vel carbonis, ad partis picturae et fumos chemicos absorbendos. Haec methodus binae stratae regulis ambientalibus et normis tutelae in loco operis conformitatem certificat.

Aeris Motus Designatio et Efficacia

Systemata Transversa, Descendentia, et Semi-Descendentia

Variis configurationibus aeris ventilandi ratio est, pro ratione modeli cabinæ pictoriæ. Syssystemata transversaria aerem a fronte trahunt eumque per tergum emittunt. Cabinæ demogrediens aerem e coelo trahit eumque per pavimentum emittit. Modelia semidemogredientia rationem mixtam sequuntur. Haec varia structura aequabilitatem aeris distributionis et efficaciam purgationis contaminatorum regunt.

Aeris Pressionis Regimen Gerere

Pressionem aeris aequatam conservare est necesse. Systemata pressionis positivi aerem purum in cabinam propellunt ne aer impurus intret, pressionis negativi autem ratio aerem contaminatum foras trahit. Rationis idonea structura ventilet aeris constantem manere, opus pictoriale expolitum fovetque a pulvere et detritu tueri.

Temperatus et Umor Imperium

Conservare Climan pro Optimo Eventu

Temperatura et humiditas directe influunt in comportamento picturae. Plurimi modelli cabinae picturae industrialis systemata HVAC integrata habent, quae ad climatem moderandum comparata sunt. Moderatio temperaturae tempus siccitiae moderatur et vitat vitia, dum humiditas constans effugat statiscitatem et incohaerentias picturae.

Tabulata Regulandi Progressa et Custodia

Systemata cabinae picturae industriali hodierna tabulis regulandi programmatibus instructa sunt. Hi operarios sinit conditiones ambientales in tempore reali custodire et mutare. Moderatio automatica clima meliorem efficit picturam et aetatem equipmentorum et filtrorum prolongat, quia vitat nimiam calorem vel nimiam humiditatem.

Salubritas et Securitas Profectus

Tutela Operariorum a Substantiis Nocivis

Bene disposita cabina pro unctione industriali minuit expositionem operariorum ad nociva VOC et particulas tenuissimas. Cum idonea filtratione et currente aere, elementa toxica efficienter removetur antequam vim adhibitam contra valetudinem respiratoriam obtineant. Multae cabinas etiam includunt instrumenta respiratoria incorporata vel compatibilitatem cum externis systematibus tutelae.

Periculi Incendii et Explosionis Minutio

Applicatio unctionis comprehendit substantias inflammabiles. Cabinae pro unctione industriali aedificatae sunt ut contineant et ventilent fumos potestative explosivos. Luminaria sine scintillis, ventilores resistentes explosioni, et materiae parietum non-combustibiles omnes conferunt ad tutiorem ambitum. Rationem qualitatis aeris esse directam rationem tutelae quia praeventione accumulationis vaporis quae ducere possunt ad eventus periculosos.

Conformatio Regulis et Officium Environmentalis

Satisfacere Standardis Qualitatis Aeris

Systemata cabinarum picturae industrialium ita comparata sunt ut normas OSHA et EPA de qualitate aeris servent. Combinatio filtrorum provectorum et ratiocinationis aeris praepollentis iuvat negotia ad normas de controlando aere purgando adaequare. Si hi normae non observentur, multae magnae et dilationes operum sequi possunt.

Minuere Impressionem Ambientalem

Efficienter arreptis VOC et pulveribus, cabina picturae industrialis emissiones in atmosphaeram minuit. Haec non solum iuvat ad leges servandas sed etiam negotium gerit ut respondeat pro salute ambienti. Nonnulli recentiores modelli motoribus ad energiam conservandam et filtris recyclabilibus instructi sunt ut magis impetus in ambientem minuantur.

Parsimonia Costuum et Efficiencia Operationis

Minutio in opere iterato et inutilitate

In regionibus regulatis vitia picturae diminuuntur, ideoque resarcitio onerosa raro indiget. Paucior pigmentum perditum et pauciores errores ad maiorem efficacitatem et meliorem rerum usum ducunt. Tandem, hoc notabiliter conservationem pecuniae in operationibus picturae efficit.

Inferiores Costus Maintenance

Cum cabina pro coloribus industriis aere puro bene utatur, vitam systematum HVAC prolongat, minuit laborem et usum instrumentorum, et imminuit frequentiam substitutionis filtrorum. Aer purus etiam componentes electronicos et instrumenta delibationis sensibilia a contaminatione defendit.

Coniunctio cum Processibus Fabrilibus Modernis

Coniunctio Processuum Sine Interruptione

Multi systemata cabinarum pro coloribus industriis ita sunt facta ut automationem adiuvant. Hae facile in brachia picturae robotica vel processus per cingula coniungi possunt. Aer purus et constans fluxus certum facit ut systemata automata sine periculo vitiorum picturae aut periculorum securitatis bene operentur.

Adaptabilitas ad Diversa Volumina Productionis

Sive in fabrica automobilorum multorum producendorum sive in officina minori speciali operando, cabinas pro coloribus industrialibus haberi in magnitudinibus variabilibus. Eorum facultas ut aera pura stabile retineant eas reddit adaptabiles mutationibus in productione sine damno qualitatis coloris aut securitatis.

FAQ

Quae genera filtrorum in cubiculo pingendi industriali adhibentur?

Omnia fere systemata combinationem filtrorum introeuntium, praefiltrorum et multi-stadium exfiltrorum adhibent quae particulas, pulverem supervolantem et vapores chimicos colligunt.

Quam saepe filtra in cubiculo pingendi industriali menda debent?

Pendet a frequentia usus, sed saepe filtra introitus et exitus hebdomade inspecta et mensis substituta debent esse ut optima operatio servetur.

Potestne cubiculum pingendi industriale temperaturam et humiditatem regolare?

Sic, multi hodierni cubiculi systematibus HVAC et regulandis instrumentis muniti sunt ad exactas conditiones ambientales retinendas.

Necessene est ut cubiculum pingendi industriale a professionista instituatur?

Institutio professionista omnia praecepta de salute, ventilatione et legibus adimplet, ideoque vehementer recommendatur pro salute et consensu.

Index Rerum

- Conservare Ambiente Purgare

- Systemata Filtrationis Aeris in Cabinis Vernici Industrialibus

- Aeris Motus Designatio et Efficacia

- Temperatus et Umor Imperium

- Salubritas et Securitas Profectus

- Conformatio Regulis et Officium Environmentalis

- Parsimonia Costuum et Efficiencia Operationis

- Coniunctio cum Processibus Fabrilibus Modernis

- FAQ