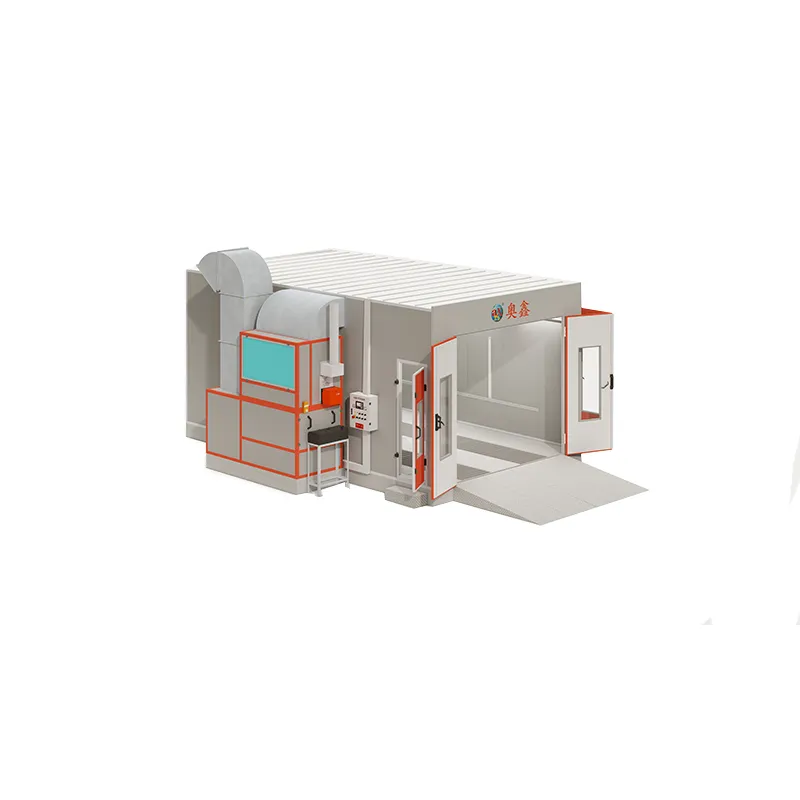

Selecting the Ideal Spray Paint Booth for Optimal Workshop Efficiency

Creating a professional finish in automotive, industrial, or artistic settings requires the right tools, and one of the most critical is the spray paint booth. Whether working with cars, furniture, or detailed components, having a controlled environment ensures consistent results, safety, and compliance with regulations. Selecting the right spray paint booth depends on understanding several key factors, including space, airflow systems, and operational requirements.

Understanding Your Workshop Needs

Evaluating Available Space

Before purchasing a spray paint booth, it’s essential to assess your workshop’s dimensions. The spray paint booth should fit comfortably within your space while allowing room for operators to move safely around it. Consider ceiling height, door width, and any other obstacles such as support columns or electrical wiring.

Determining Usage Volume and Material Type

How frequently you plan to use the spray paint booth will influence the type and durability required. Occasional use in a hobbyist setting differs significantly from high-volume production work. Also, consider the materials you spray—water-based paints require different ventilation setups than solvent-based products.

Exploring Spray Paint Booth Types

Downdraft Booths

Downdraft spray paint booths draw air from the ceiling and vent it through the floor, providing superior overspray control and reducing airborne contaminants. They are ideal for workshops requiring high-quality finishes and clean work environments but require significant investment and proper floor ventilation.

Crossdraft and Side Draft Booths

Crossdraft booths pull air from one end of the booth and exhaust it at the other, while side draft booths move air horizontally through ceiling and wall filters. These options offer more affordability and are easier to install than downdraft booths, making them suitable for smaller or mid-sized workshops.

Ventilation and Filtration Considerations

Airflow System Design

A well-designed airflow system ensures even paint application and protects workers from harmful fumes. Spray paint booths must comply with industry ventilation standards, including sufficient air exchanges per hour and the use of explosion-proof fans.

Filter Maintenance and Replacement

Filters in spray paint booths trap overspray and contaminants. Choosing booths with easily accessible filters simplifies maintenance. Regular inspection and replacement are essential to maintain air quality and extend the booth's lifespan.

Safety and Compliance

Meeting Regulatory Standards

Safety is a major concern when selecting a spray paint booth. Ensure the booth complies with OSHA, NFPA, and local fire codes. This includes fire suppression systems, proper lighting, and ventilation performance.

Fire Prevention Features

Look for booths equipped with flame-retardant materials, automatic shutoffs, and integrated fire detection systems. These features are crucial for reducing risk and ensuring your workshop operates safely and legally.

Operational Efficiency and Energy Use

Energy-Efficient Features

Energy costs can be significant, especially in large workshops. Selecting a spray paint booth with LED lighting, variable-speed fans, and efficient heating systems can reduce operating expenses. Some booths are also designed to recycle heated air, further lowering costs.

Ease of Operation and Accessibility

A user-friendly control system, proper lighting, and convenient access points can enhance productivity and reduce worker fatigue. Consider features like programmable settings, touch-screen controls, and ergonomic design.

Customization and Expandability

Modular Designs for Future Expansion

Choosing a modular spray paint booth allows for future upgrades or expansions. As your business grows, you may want to increase capacity or add features like baking cycles or automated spraying arms. A booth that supports modifications offers greater long-term value.

Tailored Options for Specialized Applications

Some workshops require specialized spray paint booth configurations for oversized parts, temperature-sensitive materials, or environmentally controlled settings. Ensure your supplier offers options tailored to your specific application.

Budget and Long-Term Investment

Balancing Cost and Quality

While it might be tempting to choose a low-cost spray paint booth, it's important to consider long-term durability and maintenance costs. A high-quality booth may have a higher upfront cost but will often result in lower operating expenses and less downtime over time.

Manufacturer Support and Warranty

Reliable technical support and a solid warranty can be just as important as the product itself. Ensure your spray paint booth comes with customer service access, spare parts availability, and coverage for structural components and critical systems.

FAQ

What type of spray paint booth is best for small workshops?

Crossdraft booths are often the most space-efficient and affordable choice for small workshops. They are easy to install and maintain, making them ideal for low to moderate usage.

How do I ensure my spray paint booth meets safety standards?

Check that the booth complies with OSHA, NFPA, and local fire codes. Look for features like fire suppression systems, proper ventilation, explosion-proof equipment, and certified lighting systems.

Are modular spray paint booths worth the investment?

Yes, modular booths offer flexibility for future expansion and customization. They allow workshops to adapt to changing production needs without needing to replace the entire system.

How often should filters in a spray paint booth be replaced?

Filter replacement frequency depends on usage and material type, but it's generally recommended to inspect filters weekly and replace them monthly or as needed to maintain optimal airflow and safety.

Table of Contents

- Selecting the Ideal Spray Paint Booth for Optimal Workshop Efficiency

- Understanding Your Workshop Needs

- Exploring Spray Paint Booth Types

- Ventilation and Filtration Considerations

- Safety and Compliance

- Operational Efficiency and Energy Use

- Customization and Expandability

- Budget and Long-Term Investment

- FAQ