Achieving Quality and Efficiency in Spray Painting

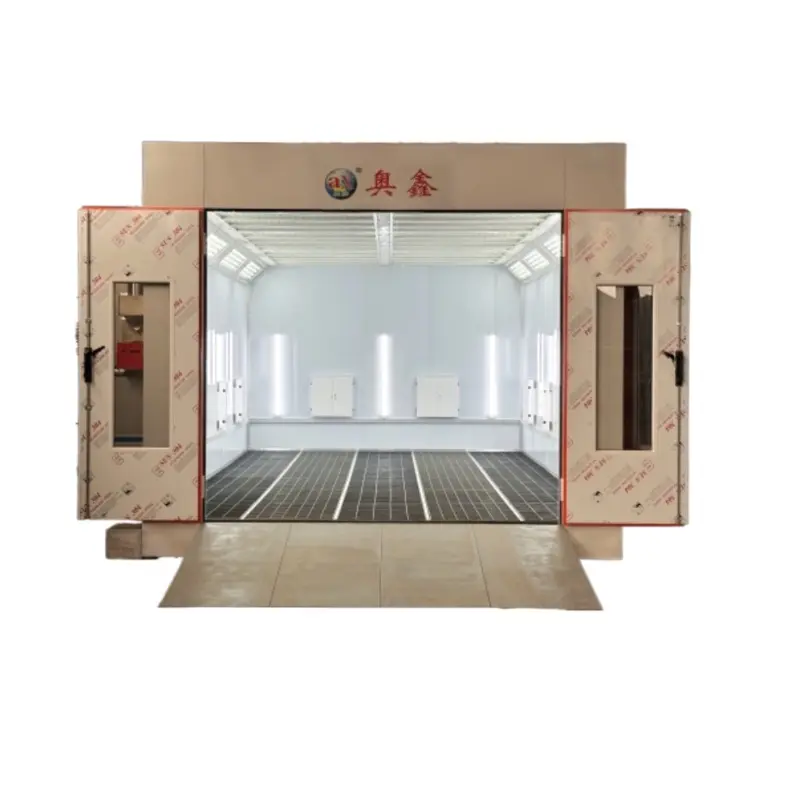

When it comes to precision, consistency, and safety in painting operations, using a professional spray paint booth is one of the most effective solutions. Whether in automotive refinishing, industrial equipment painting, or furniture manufacturing, spray booths deliver a controlled environment that enhances both the quality of the work and the productivity of the facility.

Below, we explore the top benefits of using a professional spray paint booth, how it impacts overall performance, and why investing in one is a smart long-term decision for any workshop.

Improved Painting Results

Enhanced Finish Quality

A professional spray paint booth offers a clean, enclosed space where contaminants such as dust, debris, and moisture are filtered out. This ensures a smooth and flawless finish on painted surfaces. A clean air environment is crucial, especially for automotive and industrial applications where finish quality reflects the brand’s reputation.

With advanced air filtration and ventilation systems, a spray paint booth ensures uniform application, reducing common problems like uneven coats or overspray. This directly translates into higher customer satisfaction and fewer rework costs.

Controlled Airflow and Temperature

Proper airflow and temperature control are essential for consistent paint adhesion and curing. A well-designed spray paint booth provides regulated temperature and humidity, which helps speed up the drying process and improves bonding strength. It also helps in achieving paint consistency across various parts, regardless of shape or size.

These conditions reduce variability, increase throughput, and ensure that the finished product meets exact specifications every time.

Health and Safety Improvements

Reduced Exposure to Hazardous Fumes

Paints and coatings often contain volatile organic compounds (VOCs), which are harmful to human health if inhaled over long periods. A spray paint booth is designed with proper ventilation systems that extract harmful fumes and keep the working area safe. This creates a healthier environment for painters, reducing long-term exposure risks.

Investing in a spray paint booth also helps companies meet local and international safety regulations, protecting both employees and the business from potential liabilities.

Fire and Explosion Prevention

The enclosed and fire-rated construction of a spray paint booth minimizes the risk of fire or explosion from paint fumes and airborne particles. It includes spark-resistant lighting, grounded components, and built-in fire suppression systems, offering maximum protection during spray painting operations.

For workshops dealing with flammable coatings, this level of safety is non-negotiable and essential for long-term sustainability.

Greater Operational Efficiency

Faster Turnaround Time

One of the biggest operational advantages of using a professional spray paint booth is improved process efficiency. Controlled environments reduce drying and curing time, meaning more parts can be painted in a shorter period. This allows workshops to take on more projects without compromising on quality.

Additionally, many spray paint booth models include built-in curing options or infrared heating, which can significantly shorten production cycles and improve delivery schedules.

Consistent Production Standards

Professional spray paint booths allow operators to set and maintain repeatable standards, making it easier to manage high-volume or batch production jobs. Whether spraying small components or large structures, the booth ensures consistency from one piece to the next.

This consistency not only improves customer trust but also supports quality assurance procedures, helping businesses establish reliable production workflows.

Environmental Responsibility

VOC Control and Emission Reduction

Modern spray paint booths are designed with energy-efficient filtration systems that capture overspray and reduce the release of pollutants. This supports environmental protection goals and helps businesses stay compliant with environmental laws.

Many spray paint booths include carbon filters or water wash systems to further reduce harmful emissions. This makes them a vital component in green manufacturing practices.

Waste Minimization

Using a spray paint booth helps minimize material waste. Because of the controlled spray pattern and optimized airflow, less paint is lost in overspray or mist. This not only saves on materials but also contributes to a cleaner and more sustainable operation.

For companies looking to adopt eco-conscious practices, spray booths are a step in the right direction.

Customization and Scalability

Tailored to Your Specific Needs

A key advantage of professional spray paint booths is their flexibility. From small-scale workshops to large industrial facilities, spray booths come in various sizes and configurations. Whether it’s a cross-draft, downdraft, or side-draft setup, the right spray paint booth can be customized to match the specific requirements of your application.

Custom features like integrated heating systems, control panels, and air makeup units further optimize performance and usability.

Supports Business Growth

As production needs grow, spray paint booths can be upgraded or expanded to accommodate new demands. Modular systems make it easier to scale without needing to overhaul the entire facility. This scalability allows businesses to plan for long-term growth while maintaining consistent quality and performance.

By investing in a spray paint booth that evolves with your needs, you're also future-proofing your operations.

Frequently Asked Questions

What is the main function of a spray paint booth?

A spray paint booth provides a clean, controlled environment for applying paint or coatings. It helps ensure a high-quality finish, protects workers from harmful fumes, and supports environmental compliance.

How does a spray paint booth improve safety?

Spray paint booths are equipped with ventilation, fire suppression, and filtration systems that reduce exposure to toxic fumes and minimize the risk of fire or explosion during painting operations.

Can a spray paint booth reduce production time?

Yes. By providing optimal temperature, airflow, and humidity control, a spray paint booth accelerates drying and curing times, allowing for faster project turnaround and increased efficiency.

Are spray paint booths environmentally friendly?

Many modern spray paint booths include emission control features like HEPA or carbon filters. These systems reduce VOC emissions and overspray, supporting sustainability and regulatory compliance.