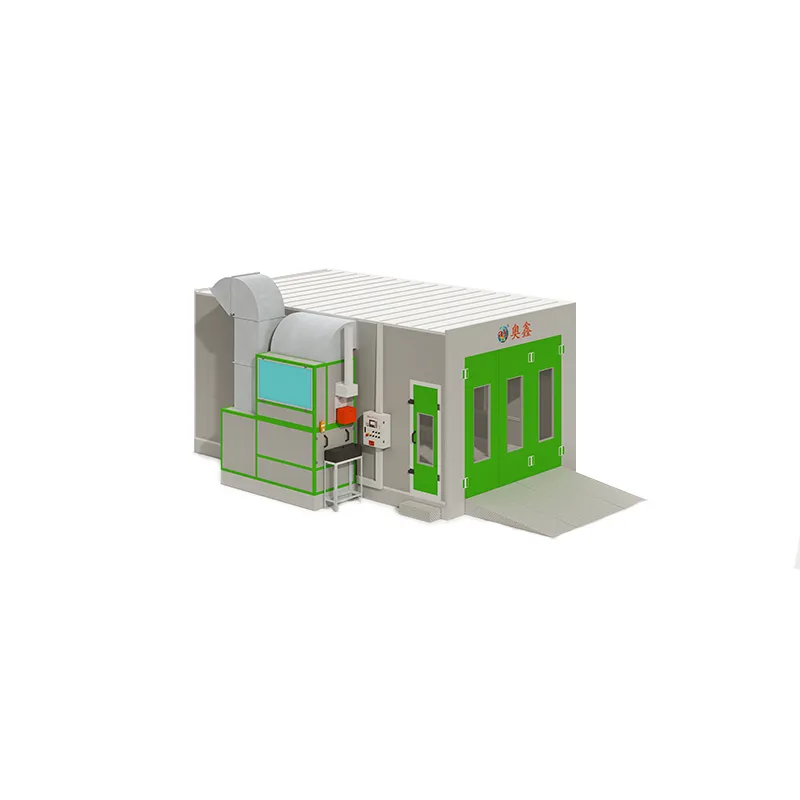

Ensuring Safety and Quality Through Proper Ventilation in Spray Paint Booths

Spray paint booths are critical environments designed to provide a controlled space for paint application. One of the most essential aspects of maintaining these booths is ensuring effective ventilation. Proper ventilation is not just about comfort; it plays a vital role in safety and the quality of the finished product. Understanding why spray paint booth ventilation matters can help operators and workshop managers create safer, more efficient working environments.

The Importance of Ventilation for Operator Safety

Reducing Exposure to Harmful Fumes

During the spray painting process, volatile organic compounds (VOCs) and other hazardous chemicals are released into the air. Without adequate ventilation, these fumes can accumulate inside the spray paint booth, posing serious health risks to operators. Proper ventilation systems help remove these airborne contaminants, ensuring cleaner air and reducing the chance of respiratory issues, dizziness, or long-term health effects.

Preventing Fire and Explosion Risks

Spray paint booths handle flammable materials, and the buildup of overspray and fumes increases the risk of fire or explosion. Ventilation systems are engineered to maintain airflow that prevents hazardous concentrations of flammable vapors. This reduces the likelihood of ignition sources causing accidents, thereby protecting personnel and equipment.

Enhancing Paint Quality Through Controlled Airflow

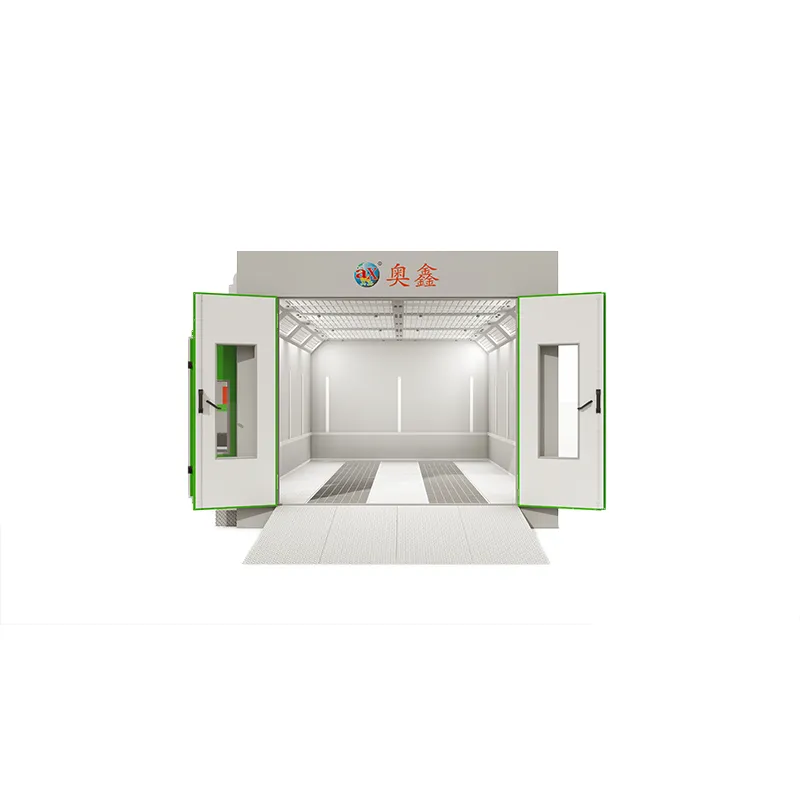

Minimizing Overspray and Contaminants

How does ventilation affect the finish of painted surfaces? Proper airflow within the spray paint booth helps control overspray by directing paint particles away from the working area and into filtration systems. This minimizes contamination and ensures a smooth, even paint coat, which is critical for professional results.

Maintaining Optimal Temperature and Humidity

Spray paint booth ventilation also regulates temperature and humidity, two factors that significantly influence paint adhesion and drying times. Consistent environmental conditions inside the booth allow for predictable curing and reduce defects such as blistering or cracking, ultimately improving the durability of the paint job.

Key Components of an Effective Ventilation System

Intake and Exhaust Fans

Ventilation systems rely on a balance between intake and exhaust fans to create a continuous flow of fresh air. Intake fans bring in clean air while exhaust fans remove contaminated air from the booth. The correct sizing and placement of these fans are crucial to maintain the desired airflow rate, which depends on the booth size and type of paint used.

Filtration Units

Filtration is a vital part of spray paint booth ventilation. Filters capture overspray particles and harmful chemicals before air is exhausted outside or recirculated. Different types of filters, such as pre-filters and HEPA filters, are used depending on the level of contaminants and the specific application. Maintaining these filters regularly is essential for sustained system performance.

Regulatory Standards and Compliance

Meeting Environmental and Safety Regulations

Spray paint booth ventilation must comply with local and international regulations regarding air quality and worker safety. Regulations often specify minimum airflow rates, filter efficiency, and emissions limits. Adhering to these standards not only ensures legal compliance but also contributes to a safer workplace and environmental protection.

Importance of Regular Inspection and Maintenance

How often should ventilation systems be inspected? Regular inspection and maintenance are vital to ensure the system operates at peak efficiency. This includes checking fans, replacing filters, and inspecting ductwork for leaks or blockages. Neglecting these tasks can lead to reduced ventilation effectiveness and increased safety risks.

Best Practices for Optimizing Spray Paint Booth Ventilation

Designing for Proper Airflow Patterns

Effective ventilation design involves creating airflow patterns that sweep across the painting area, removing contaminants efficiently without causing turbulence that could affect the paint finish. Consultation with ventilation experts during the booth design phase can optimize these patterns.

Training Operators on Ventilation Usage

Operator behavior impacts ventilation effectiveness. Training staff to use ventilation controls properly and recognizing signs of ventilation failure is essential. Encouraging operators to report issues promptly helps maintain system reliability and safety.

FAQ

What is the ideal airflow rate for a spray paint booth?

The ideal airflow rate depends on the booth size and type of paint, but generally, the airflow should replace the booth's air volume multiple times per minute to ensure effective contaminant removal.

How often should spray paint booth filters be replaced?

Filters should be checked regularly and replaced according to manufacturer recommendations or when airflow decreases noticeably. Frequency can range from monthly to quarterly based on usage.

Can ventilation problems affect the quality of paint finishes?

Yes, inadequate ventilation can cause uneven airflow, leading to overspray buildup, contamination, and defects such as runs or sags in the paint finish.

Are there specific regulations for spray paint booth ventilation?

Yes, ventilation must meet OSHA, EPA, and other relevant local regulations concerning air quality, worker safety, and emissions control.

Table of Contents

- Ensuring Safety and Quality Through Proper Ventilation in Spray Paint Booths

- The Importance of Ventilation for Operator Safety

- Enhancing Paint Quality Through Controlled Airflow

- Key Components of an Effective Ventilation System

- Regulatory Standards and Compliance

- Best Practices for Optimizing Spray Paint Booth Ventilation

- FAQ